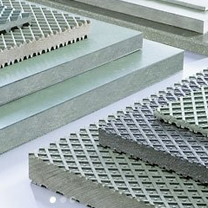

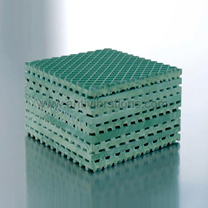

BILZ vibration isolation (anti-vibration) pad materials are highly developed, designed to solve problems caused in many industrial sectors by vibrations and structure borne noise. Made from a precise combination of nitrile rubber, cork particles and cross linked polyester fibers, these high grade compound materials possesses excellent physical and mechanical properties.

One major advantage of these new compound materials are their resistance to modern cooling lubricants; the mountings can be used in oil sumps without any loss of their physical properties. Particularly worth mentioning are the superb “compression set” values. These are extremely important, for example, if modern machine tools are to be mounted in isolation while ensuring long term geometric position. 8 different types of pads provide the technically optimal solution to almost any vibration problem. The primary aim in the development of these vibration materials was to provide specific solution for a wide range of machinery for e.g. lathes, milling machines and grinding machines, as well as presses and feed press.

The service life of these mounting pads is nearly unlimited if the load values are observed. No permanent deformation will result.

Extremely high degree of resistance to conventional oils, grease, acids, etc. Completely resistant to cooling emulsions, thus allowing machine mounting in oil sumps.

+120o to - 20o C + 250o to 5o F

Range of application: BILZ leveling elements BNS are specially suited for the positioning of presses, automatic stamping machines automatic die casting machines etc.

Range of application: BILZ leveling elements BNS are specially suited for the positioning of presses, automatic stamping machines automatic die casting machines and for all machines which have to be mounted to the floor.

Range of application: Models BNVS & BNRS are used in cases where a film connection of the element to the machine is desirable Angle differences are equalized by means of the movable leveling screw

Range of application: Provides good vibration and structure borne noise isolation. Provides high quality vibration and structure borne noise isolation.

BILZ Precision Leveling Wedges are manufactured in three different models; free standing (PK Series), bolt-on to the machine (PKA eries), bolt-through to the floor, foundation (PKD Series). This design permits the highest precision leveling range, to within 0.0004" (0.01mm). Our self-locking design prevents creep from the installed position. Large support surfaces provide optimum foundation support and rigidity. Any of the BILZ Isolation materials can be bonded to the and/or bottom of the levelingwedge to provide the required vibration isolation.Machine leveling with Bilz leveling wedges is very fast and efficient, especially when compared to other machine levelers or leveling feet. The full weight of the machine can be applied directly to the leveling wedge and the leveling wedge can be adjusted to level the machine. This allows you to reduce the time needed for rented equipment such as portable cranes and fork lifts. Once the machine is set onto the leveling wedges, initial adjustments of the leveling wedges can be carried out with a torque wrench to assure that equal loading is applied to each leveling wedge. A precision machinist level can then be used to finely adjust each leveling wedge to accurately level themachine to within 0.0004" (0.01mm).

Rubber air spring for highly effective isolation of machinery and subassemblies against shock and oscillation. The bell shaped component is made of high grade elastomer. The construction allows a highly effective isolation without the disadvantage of excessive horizontal deflection. It is impossible for the element to break down as a result of overloading or a sudden drop in pressure. To reduce vertical dampening, the component is available with additional attenuation, see FAEBI®-HD below. The base plate is equipped with an anti-slip pad so there is no need to anchor the machine to the floor. Note: For outdoor use (e.g. isolation of a roof top air condition unit) the FAEBI® can be supplied in a stainless steel and EPDM elastomer version.

Range of Application: Excellently suited for active isolation of high speed power presses, forging hammers as well as other machines and equipment with high dynamic forces. Passive isolation of measuring and testing machines as well as high precision machine tools. Systems can also be supplied with an option of electronic or mechanical level control!

Wiith deep natural frequency & adjustable dampening (pat.) for vibration isolation of measuring & testing machines, optical and electronic equipment, laser machines, fine machining plant, vehicle & motor performance testers etc.

The Air Spring Isolator BiAir® consists of either a steel or cast aluminum body whose air volume is enclosed by a thin-walled, flexible and pressure-resistant rolling diaphragm. The piston is seated on this diaphragm & is pushed into the air volume.

This design causes highly effective vibration isolation. In order to obtain as high a dampening effect as possible, the air space is split into two chambers (load and dampening volume) that are connected by an air tube. The amount of dampening can be easily changed by the adjustable valve located on the outside of the air spring. As the load on the air spring changes, air is forced through the bypass valve creating friction. This friction creates up to an 18% dampening effect. Additional safety valves protect the rolling diaphragm from getting damaged by over inflation.

Range of Application: Highly effective vibration isolation of sensitive measuring (CMM) and testing machines, fine machining plant, as well as optical and electronic equipment. Another important range of application is the vibration isolated foundation of vehicle, motor and other performance testers.

BiAir® Air Spring isolators are extremely well suited for the isolation of foundations e.g. equivalent machine loads.

Air springs with higher max. loads as well as air springs with lower natural frequencies can be supplied upon request!

Active vibration isolation system providing control by means of electro-pneumatic in either 3 or 6 Degrees Of Freedom.

Range of Application: Optimal active vibration isolation performance for machines with high dynamic forces that are performing sensitive measurements and inspections, lithography equipment, laser machines, high resolution electron microscopes, interferometer & machinery for the semiconductor industry.

The Active vibration isolation system AISTM is utilized when the efficiency of isolation and the settling time of conventional air spring with electro-pneumatic leveling systems is insufficient.

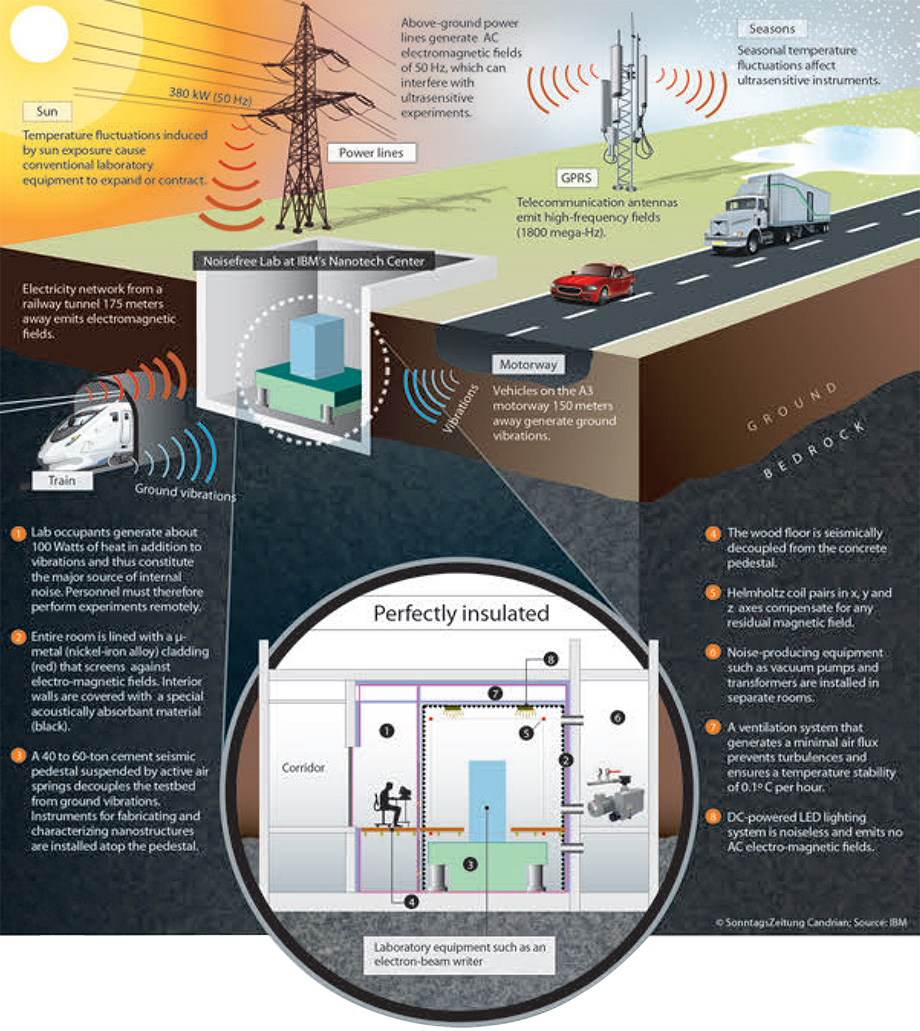

Effective and reliable shielding from low frequency magnetic fields for highly sensitive devices and applications such as electron microscopes, nanotechnology and biomagnetic examinations.

Disturbing influences are extensively neutralised with opposing fields with reversed polarity. Cable loops are laid around the work area to be protected and opposing fields are generated in real time using magnetic field compensation devices that continuously measure the actual electromagnetic value.

This method is an effective and cost-efficient alternative to expensive magnetic field shielding, for example with metal.

Bilz acoustic elements enable optimized room acoustics and airborne noise insulation in office and industrial buildings, laboratories and test cells.

Our high-quality solutions for absorbing noise energy are distinguished by maximum noise insulation and minimisation of the associated sound pressure levels and the resulting resonance period.

VITAP® - Vibration Isolated Table Top Platforms. These lightweight platforms consist of a robust, powder coated metal enclosure with either three or four integrated low natural frequency BILZ rubber air springs FAEBI® or the even lower natural frequency BILZ membrane air springs BiAir®. Platforms are available with or without a leveling system; automatic or manual leveling systems are available. Standard platforms are supplied with a granite top which provides a polished surface with high mass & stiffness.

These platforms are designed for a wide range of applications with loads from 1kg to 150kg. These include visual devices, light microscopes, microscopes with CCD camera, inspection microscopes, small surface and roundness testers, lab and measurement rooms as well as semi clean rooms. They are also well suited for portable use.

BILZ insulated table LTH is a vibration insulated workplace. Vibration of the surrounding area is insulated by high efficient membrane air springs. The level controller (mechanical-pneumatic valves) will maintain a level accuracy of ± 1/100 mm or ± 1/10 mm automatically even while the loading may change. An air regulator with water trap and air filter is included.

As standard the insulated table is available in 3 different sizes. We are always pleased to fulfill custom made sizes and colours. The work surface of the table can be delivered in granite (LTH).

Range of Application: Vibration sensitive measuring and testing machines, laser, scales, optical and electronically as well as medical equipment. The new insulated table LTH is used for all applications where vibrations or load changes may disturb the experiment or machine.

In recent years, ever higher requirements of test stands and test systems for the automobile industry have led to the need for improved performance of vibration isolation systems. BILZ air-springs with level control systems are ideally suited for this demanding application.

During the vibration insulation of test stands and aggregates with high dynamic forces additionally a seismic mass is needed.

The main purpose of the foundation is to stabilize the machine as well as to increase the moment of inertia. The foundation thus positively influences machine vibration by reducing the amplitude of oscillation. It is wrong, however, to assume that any foundation large enough would eliminate all vibration problems. It is important that as much information as possible be supplied regarding the machine to be isolated, this will include machine size and weights, any dynamic features of its operation, location including ground type, condition where optimal performance is required and a vibration analysis of the machine and site conditions. A correct isolation between machine foundation and the surrounding area will result in trouble free operation. As a result of years of experience we have the necessary experience in this field. At your request we can offer all other related services including measuring of vibrations, planning and construction design.

We use the most modern measurement equipment (FFT-Analyzer + PC calculation programs). Our decades of experience in the field of vibration technology guarantees technically and economically reliable solutions for your problems.

The first step is to determine the maximum measured vibrations for each of the three vectors x, y and z. The largest of the three values is to be compared to the limit curve graph of the machine.

Anti Vibration Solutions for Press Machines, Milling and Drilling Machines, CNC Turning and Machining Centers, Surface and Cylindrical Grinders, Injection Moulding Machines, High Speed Power Press, Forging Hammers, CMM Machines, Microscopes, Surface and Roundness Testers, Printing and Packing Machines, etc.